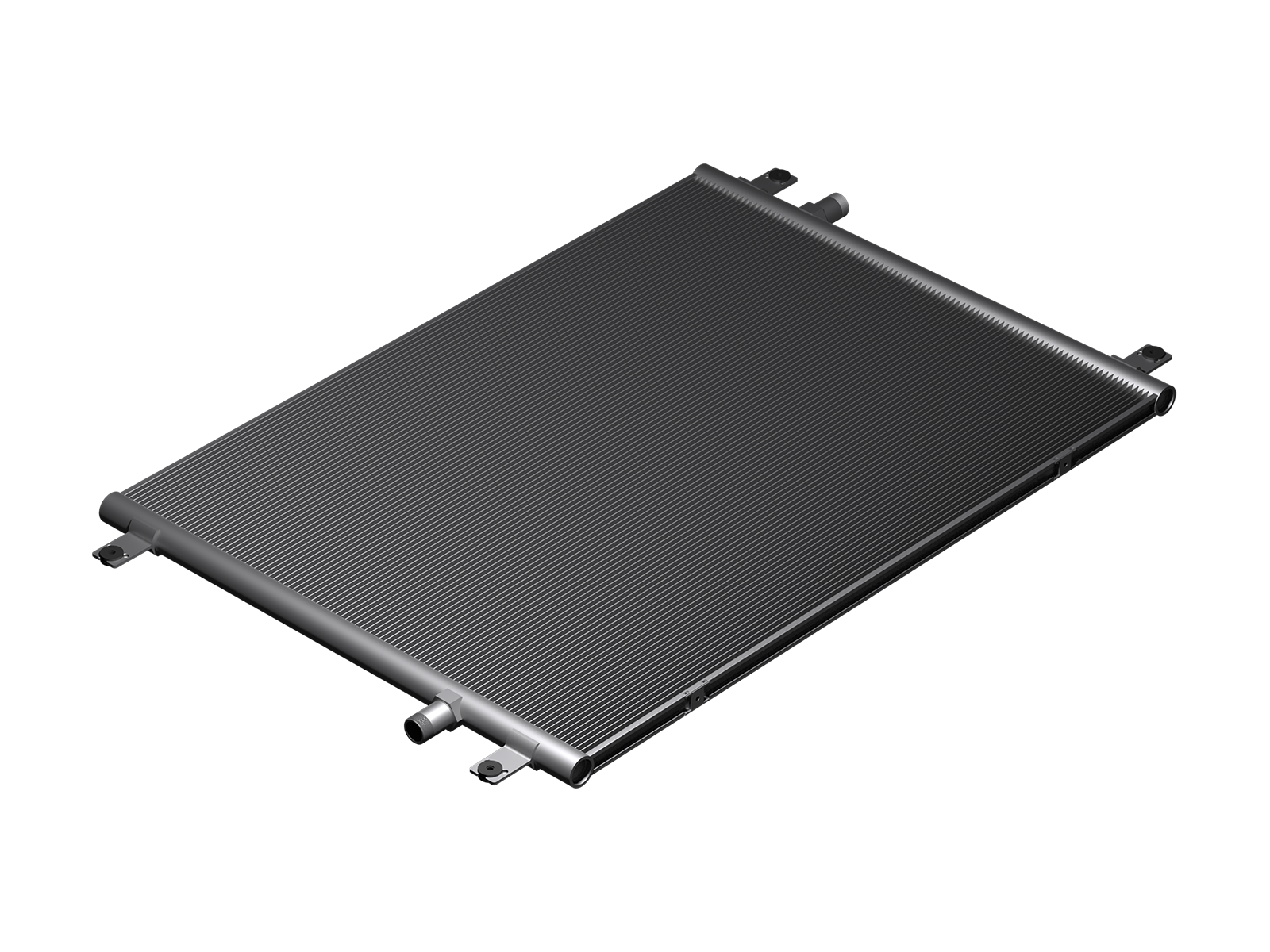

In the realm of heating, ventilation, and air conditioning (HVAC) systems, achieving optimal cooling efficiency is paramount. Microchannel evaporators, a type of microchannel heat exchanger, have revolutionized the industry with their superior performance and innovative design. This article delves into how microchannel evaporators enhance cooling efficiency, making them an integral component in modern HVAC systems.

Superior Heat Transfer Capabilities

The primary advantage of microchannel evaporators lies in their exceptional heat transfer capabilities. Traditional heat exchangers often struggle with efficiency due to their design limitations. In contrast, microchannel heat exchangers are engineered to maximize surface area and heat transfer.

- Increased Surface Area: Microchannel evaporators consist of flat tubes with numerous small channels, or microchannels. This design significantly increases the surface area available for heat exchange. More surface area means more efficient absorption and release of heat, which enhances the overall cooling process.

- Enhanced Conductivity: The materials used in microchannel heat exchangers, typically aluminum, offer excellent thermal conductivity. This property allows for rapid heat transfer from the refrigerant to the air, ensuring that the cooling process is both quick and efficient.

Reduced Refrigerant Charge

Another critical factor contributing to the improved cooling efficiency of microchannel evaporators is their reduced refrigerant charge. Traditional systems often require large amounts of refrigerant to operate effectively, which can be both costly and environmentally damaging.

- Efficiency in Design: The compact and efficient design of microchannel evaporators means that less refrigerant is needed to achieve the same cooling capacity as traditional systems. This reduction not only lowers operating costs but also minimizes the environmental impact associated with refrigerant production and disposal.

- Environmental Benefits: Using less refrigerant helps in reducing greenhouse gas emissions, as many refrigerants have high global warming potential. This makes microchannel heat exchangers a more eco-friendly choice, aligning with global efforts to combat climate change.

Lower Pressure Drop

Pressure drop is a common issue in traditional heat exchangers, leading to decreased efficiency and increased energy consumption. Microchannel evaporators are designed to minimize pressure drop, enhancing the overall efficiency of the cooling system.

- Optimized Flow Paths: The microchannel design allows for smoother flow paths, reducing resistance and pressure drop within the system. This optimization means that less energy is required to circulate the refrigerant, leading to significant energy savings.

- Energy Efficiency: By minimizing pressure drop, microchannel evaporators reduce the workload on compressors and other components of the HVAC system. This reduction in workload translates to lower energy consumption and operating costs, making the system more efficient overall.

Compact and Lightweight Design

The compact and lightweight nature of microchannel evaporators offers several advantages, particularly in terms of installation and integration into existing systems.

- Space-Saving: The slim profile of microchannel heat exchangers allows them to fit into tighter spaces, making them ideal for use in modern, compact HVAC systems. This space-saving design is particularly beneficial in urban environments where space is at a premium.

- Ease of Installation: The lightweight construction of microchannel evaporators makes them easier to handle and install, reducing labor costs and installation time. Additionally, their design allows for greater flexibility in system design and integration.

Durability and Longevity

Microchannel evaporators are built to last, offering superior durability compared to traditional heat exchangers. This longevity not only reduces maintenance costs but also ensures consistent performance over time.

- Corrosion Resistance: Aluminum, the primary material used in microchannel heat exchangers, is highly resistant to corrosion. This property extends the lifespan of the evaporators, reducing the need for frequent replacements and maintenance.

- Robust Construction: The design of microchannel evaporators makes them more resistant to mechanical damage and wear. This robustness ensures reliable performance even in demanding conditions, contributing to the overall efficiency and reliability of the HVAC system.

Applications in Various Industries

The benefits of microchannel evaporators extend across various industries, from residential and commercial HVAC systems to automotive and industrial applications.

- Residential and Commercial HVAC: In residential and commercial buildings, microchannel heat exchangers provide efficient cooling, enhancing indoor comfort while reducing energy costs.

- Automotive Industry: In automotive applications, microchannel evaporators help improve fuel efficiency and reduce emissions by providing effective cooling for air conditioning systems.

- Industrial Processes: In industrial settings, where precise temperature control is critical, microchannel evaporators offer reliable and efficient cooling solutions, ensuring optimal operation of machinery and processes.

Conclusion

Microchannel evaporators significantly enhance cooling efficiency through superior heat transfer capabilities, reduced refrigerant charge, minimized pressure drop, and durable design. These advantages make them a valuable component in modern HVAC systems, offering both economic and environmental benefits. As industries continue to prioritize efficiency and sustainability, the role of microchannel heat exchangers in improving cooling performance will undoubtedly grow, driving innovation and progress in thermal management solutions.